First ESCO

Think of Heat to Power , think of First ESCO. We are the fastest growing Energy Service Company with expertise mainly in designing and supplying affordable waste to heat power plants , designing an efficient fuel switching alternative with petcoke etc. The amount of heat that is presently let out in to atmosphere as waste is too huge . The power that could be generated from this wasted heat is enormous. Power generated from waste heat is Green energy which reduces the carbon foot print.

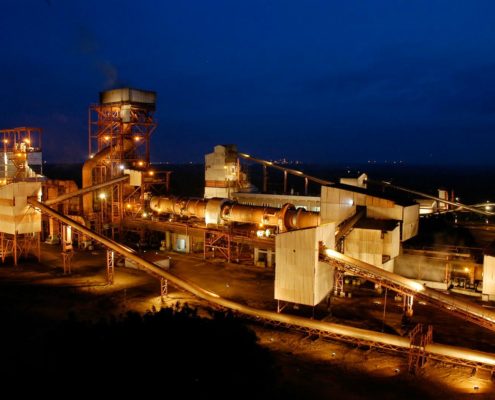

We have successfully installed our state of the art 2.7MW Waste heat recovery ORC Power Plant at Pioneer Cement Industries, Al Ghail Industrial Area , Ras Al Khaimah , UAE as a first phase out of two phases, Once phase -2 of the project is installed the total Gross power generation would be 4 MW. This is the first such plant in Asia and Middle East. Entire plant has been built with in house design and engineering.

On implementation of both phases of the project PIONEER CEMENT will have a capacity to generate 32 Million kWh/Year due to the Waste heat recovery Project (including energy savings due to stopping the gas cooling forced draft fans to an extent of 500 KW ) . Hence POINEER CEMENT can avoid purchase of Energy to that extent and save US$ 3,800,000 per year at a tariff of 12 US Cents/kWh.

With this projected savings, Pioneer cements will have a very attractive payback for the investment. Click here for a case study of this project.

Talk to our Energy Expert Today for a free analysis of how much power we can recover from your waste heat.